BABBCO Tunnel Oven Manufacturers

3D SolidWorks Design Software

Approaching Engineering as a Collaborative Process—From Beginning to End

Early in our history as a leading tunnel oven manufacturer, we learned that the secret to building a great custom tunnel oven is involving customers in the design process from beginning to end.

We start by learning everything we can about your goals, challenges, facilities and bakery products. Then, we collaborate with you to identify the type of oven and features that will give you the best results. This all-important discovery phase often happens in our Innovation Center, where you can test your bakery products, and experiment with different oven types and baking techniques. At this stage, we can also show you how to lower operating costs, improve energy efficiency, shorten bake times and simplify operations.

All of this goes into the development of a tunnel oven design that serves as a blueprint for our tunnel oven manufacturers. Your input is critical throughout the engineering process, which includes:

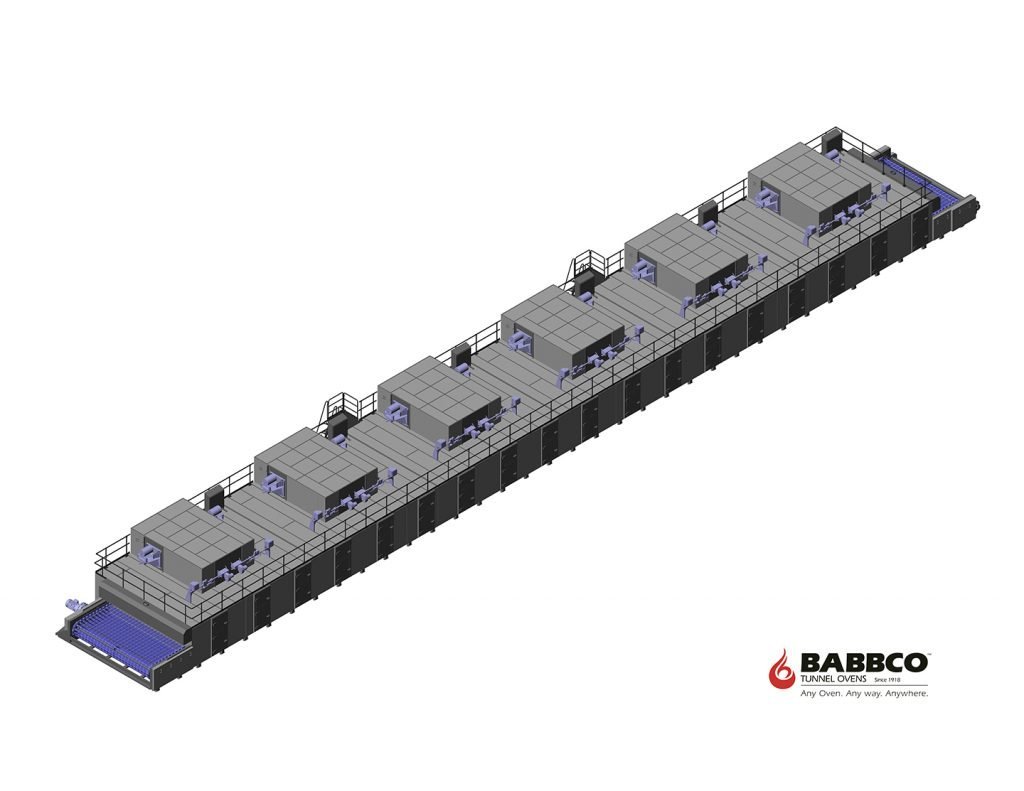

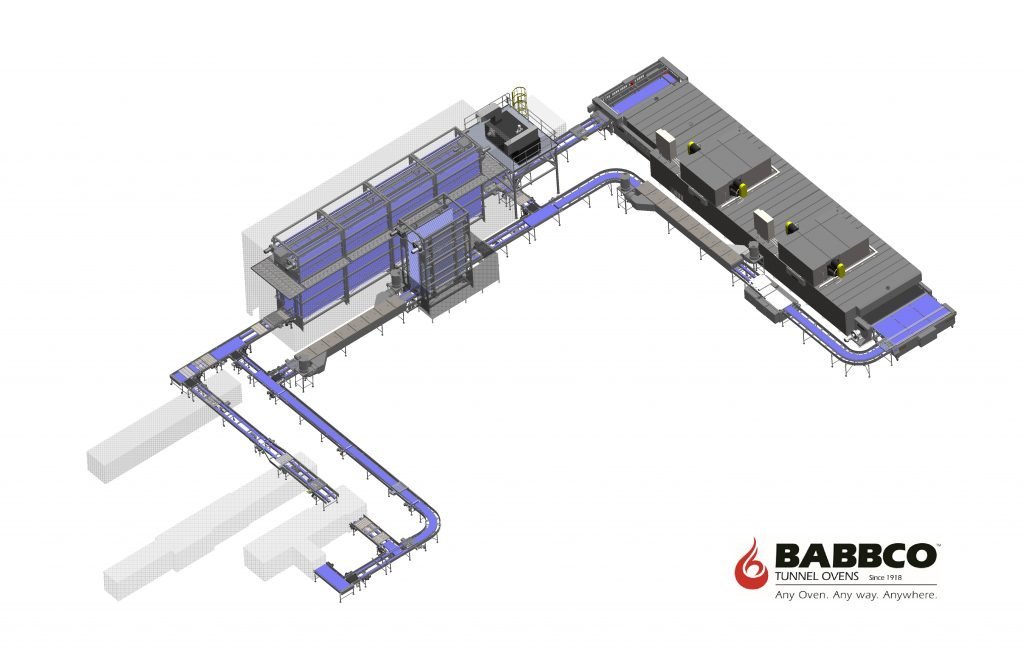

- Creating a CAD model on SolidWorks' advanced, 3D mechanical design software

- Optimizing airflow designs and ensuring even heat distribution with computational fluid dynamics technology

- Fine-tuning and adjusting the design based on your specifications and real-time input

- Developing a plant layout to ensure that your BABBCO tunnel oven fits and complements your space

- Getting your approval on the final oven design, before electronically transmitting the specifications via network to BABBCO manufacturing